Dmg Automation Gmbh

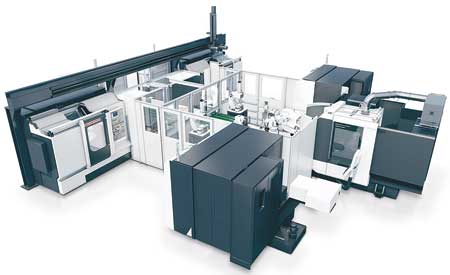

The automation expertise for pallet handling is directly integrated into the production plants of DMG MORI. The interplay between engineering from the DMG MORI production plants and automation expertise on the part of DMG MORI HEITEC provides the user with a customized, integrated, and reliable solution – and everything from a single source. We are always looking for new methods and technical possibilities that allow us to respond to your needs and wishes. This is made possible by our highly experienced engineers and designers, as well as our expert staff in sales, development, production, assembly and quality assurance. Automation solution extremely flexibly adapted to the MILLTAP 700. High degree of autonom. MILLTAP 700 with WH 3 – quick and precise for maximum productivity. Contact T +49.7121.894-183 E [email protected]. FAQ Express delivery Support ©2019 by Berghof Automation GmbH Contact & Legal Notice. Innovation Days automation display. This feature is not available right now. Please try again later.

Dmg Automation Gmbh Llc

Bielefeld // Two strong partners are combining their know-how to speed up the development of innovative automation solutions: DMG MORI AKTIENGESELLSCHAFT and HEITEC AG are founding the joint venture “DMG MORI HEITEC“ – perfectly timed to coincide with the start of the SPS IPC Drives in Nuremberg, the leading trade fair in Europe for electric automation.

Through DMG MORI HEITEC GmbH the two companies are continuing their successful collaboration over the past years and are mutually strengthening their market position in the fast-growing field of automation. Of the more than 1,000 employees at the HEITEC group, around 600 work on automation solutions. One in four new machines from DMG MORI is already provided with an automation solution. In future every machine shall be fitted with automation on the basis of a modular system. By modular-based compatible solutions DMG MORI HEITEC will supply small and medium-sized companies with an integrated automation concept.

Dmg Automation Gmbh Group

Software-based support for engineering processes using virtual models of machines, plants, robot applications and material flows is an essential measure to reduce costs, while simultaneously increasing productivity. DMG MORI HEITEC GmbH, based in Erlangen, has therefore set itself the goal of developing a virtual representation – in short “digital twin”. With the aid of digital engineering, project lead times can be cut by around 20%, and commissioning on site can be even more significantly reduced by up to 80%. Future additions or changes can be planned and tested with the digital twin running in parallel to the live operation.

“We are strengthening our automation expertize as two equal partners in a joint venture. Thus, the development of the digital twin is of key importance: it speeds up and stabilizes all the customer processes – from development and setting up right through to service – and ensures flexible, steady procedures,“ says Christian Thönes, Chairman of the Executive Board of DMG MORI AKTIENGESELLSCHAFT.

“Through automation and digitalization we are making a significant contribution towards increasing productivity and efficiency. Supported by digital engineering we are achieving a considerably higher quality with shorter through-put times in development and commissioning,” says Richard Heindl, Chairman of the Executive Board of HEITEC AG.

In the future, automation standards are also planned for a broad range of customer sectors and the realization of customized projects specifically for medium-sized companies, that is, the German “Mittelstand“.

Dmg Automation Gmbh Inc

Bielefeld. As per end of the first half-year, GILDEMEISTER has acquired WKZ Werkzeugmaschinen GmbH. This company based in Hüfingen, Baden-Württemberg, designs and manufactures integrated solutions including robot systems for machine tool automation.

The key strength of WKZ is the integration of robot technologies, controls and components. Combined with innovative lathes and milling machines, automated workpiece handling solutions increase productivity, especially for customers in the series production segment. The company founded in 1994 merges technical expertise in both industrial automation and component manufacturing with a strong customer focus and high degree of flexibility. In the past few years, WKZ developed profitably, achieving sales revenues of approx. Euro 6 million in 2006. GILDEMEISTER plans to further expand the company’s business mainly by rounding off its product offerings and intensifying sales and service activities. Within a year, the company aims to achieve sales revenues in the amount of approx. Euro 15 to 20 million.

Free mac cleaner 10.6.8. GILDEMEISTER intends to strengthen its market position in the growing automation segment. /download-nordvpn-for-mac.html. In the future activities will be concentrated in “DMG Automation GmbH”. This group company will be presented already at EMO 2007 in Hanover, the world’s largest trade fair of the machine tool industry. GILDEMEISTER will publish its interim figures for the first half of 2007 on 2 August 2007.

GILDEMEISTER Aktiengesellschaft

The Executive Board