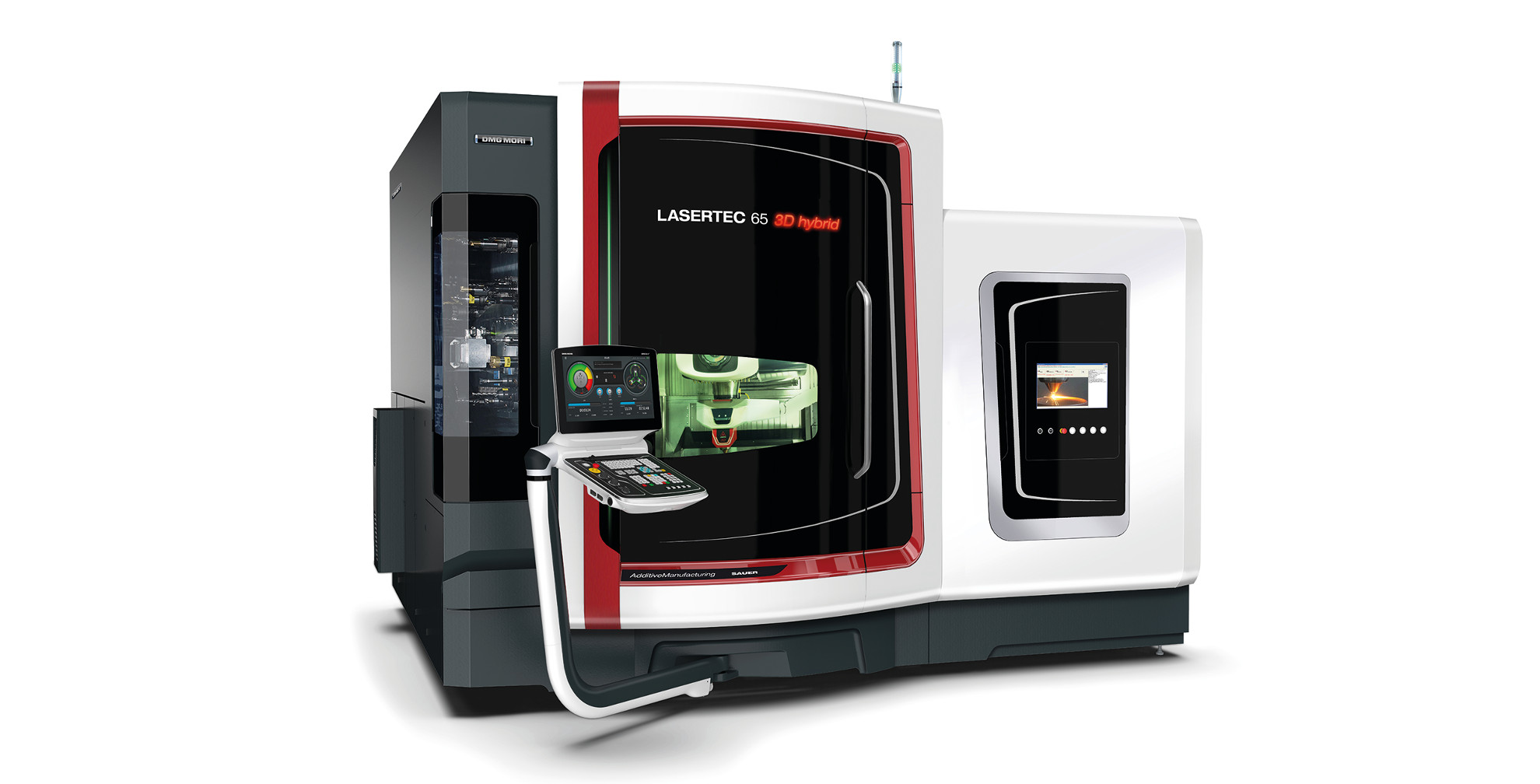

Dmg Mori Lasertec 65 3d

Feb 01, 2014 DMG Mori Lasertec 65 high end hybrid metal 3d printer and 5 axis mill When you see this machine at work, you see the future of production. The turbine housing just grows in front of you. /death-from-above-doing-600-dmg.html.

In times of ever shorter product life cycles and increasingly more complex and more individualised bespoke components, additive manufacturing processes can help companies to manufacture produce new and innovative products more quickly. Additive manufacturing processes enable complex geometries and workpieces to be produced. The unique technology combination of laser metal deposition by means of a powder nozzle and milling gives the user completely new application and geometry options. With the LASERTEC 65 AdditiveManufacturing, SAUER LASERTEC now offers a hybrid solution for combined laser deposition welding and 5-axis milling. This method uses a deposition process by means of a powder nozzle, which is up to 20 times faster than generation in a powder bed.

The market for additive processes has grown rapidly in the past. However, up to now, these have been restricted to the production of prototypes and small parts, which otherwise could not have been manufactured using any other conventional method. With the combination of the two processes, metal deposition and chip removal, on one machine, additive technology supplements and enhances traditional machining methods.

For generative manufacturing, the LASERTEC 65 AdditiveManufacturing is equipped with a 2 kW diode laser for laser deposition welding, while the fully fledged 5-axis milling machine from DECKEL MAHO in robust monoBLOCK® design also enables highly accurate milling operations to be carried out. “Thanks to the fully automatic changeover between milling and laser operation, the LASERTEC 65 AdditiveManufacturing is suitable for the complete machining of complex components with undercuts as well as for repair work. It is also ideal for the application of partial or complete coatings for mould making and mechanical engineering or even medical engineering”, explains Friedemann Lell, Sales Director, SAUER LASERTEC, in Pfronten.

Producing large parts generatively

In contrast to laser melting in a powder bed, laser deposition welding enables large parts to be manufactured using a metal powder nozzle. With a deposition rate of up to 3.5 kg/h, this process is up to 20 times faster than the laser generation of parts in a powder bed. The combination with milling opens up completely new applications. The component can be built up in several steps, whereby milling can be interspersed with deposition welding in order to allow areas, which the cutter would no longer be able to reach when the component was finished due to the component geometry, to be machined to final accuracy.

The hybrid machine combines the advantages of milling, such as high precision and surface quality, with the flexibility and high deposition rate of laser welding. /can-you-download-netflix-shows-on-a-mac.html. “In the case of some components, where today 95 % of the material is removed by milling, with additive processes, material is only built up where it is needed. As result, material loss is reduced to 5 %. This leads to significant raw material and cost savings”, explains Friedemann Lell.

The laser, complete with powder deposition head, is fitted into the HSK toolholder of the milling spindle. It can be automatically parked in a secure docking station while milling operations are being carried out on the machine.

The machine is controlled by means of a 19” ERGOline® with Operate 4.5 on SIEMENS 840D solutionline. The controller for the laser process is mounted in a separate electrical cabinet, which makes it easier to integrate this system into other DMG MORI machines.

Production of 3D contours

By means of a laser diode, the metal powder is deposited in layers onto a base material, and fuses with it without pores or cracks. In doing so, the metal powder forms a high-strength welded bond with the surface. A coaxial inert gas prevents oxidation during the build-up process. After cooling, a layer of metal which can be mechanically machined is produced.

As laser deposition welding has long been established as a stand-alone technology, it is ideal for incorporating into DMG MORI’s high-quality CNC machines. “The combination of chip-removal and additive processes will become more important in future, as it opens up many new options and advantages for the user”, says Lell.

One strength of this process is the option to successively build up layers of different materials. Wall thicknesses of 0.1 mm to 5 mm are possible depending on the laser and the nozzle geometry.

Complex 3D contours can also be generated in layers without supports.

The individual layers can then be accurately machined before the areas become inaccessible to a cutter or other tools due to the component geometry. The combination of the two processes is a sensible choice for repair work and the production of mould tools. However, it also offers many interesting options for lightweight components, prototypes or small batches production – particularly in the large-part manufacturing sector where other additive manufacturing processes cannot be used due to limited space.

Economical solution

Large machines, such as those used for machining bulky components in the energy or aerospace industries, tend to be expensive. If roughing, deposition and finishing are reduced to a single machine, this represents a financially advantageous solution for the customer.

Furthermore, in the energy and oil industry, components often have to be coated with corrosion-resistant alloys to protect against wear. Deposition welding provides protection for products such as tubes, fittings, flanges and special products which are used in aggressive environments. With a hybrid machine, machining of the base material, coating and finishing can be carried out on one machine. This results in cost savings and a reduction in throughput times.

Dmg Mori Lasertec 65 3d Preis

Highlights of the LASERTEC 65 AdditiveManufacturing

- Unique combination of laser metal deposition and milling provides optimum surface finish and component precision

- Laser deposition welding with powder nozzle: 20x faster than powder bed processes

- Ability to produce complete components

- Many 3D geometries, including undercuts, can be realised without supporting structures

- Repair of turbine components and in tool/mould making

- Application of wearing surfaces

- Complete machining with fully automatic changeover between milling and laser operation

- Large work area for workpieces up to Ø 650 mm, 360 mm in height and max. 1,000 kg

- Accessibility and ergonomics: Door opening 1,430 mm, optimum access from the front

- Low space requirement with 7.5 m² footprint

Dmg Mori Lasertec 65 3d Hybrid

Sourceen.dmgmori.com